Ensuring a Bright Future for Diamond Electronics and Sensors

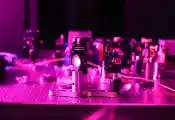

Nov. 5, 2024 -- One new study, conducted by researchers at the U.S. Department of Energy’s (DOE) Princeton Plasma Physics Laboratory (PPPL) and Princeton University, investigated ways to reliably grow diamond at lower temperatures than those currently used. Diamond has properties that make it attractive to the semiconductor industry. With its particular crystal lattice structure, diamond can withstand high electrical voltages. It’s also very good at dissipating heat.

Growing diamond in a laboratory typically involves high heat beyond what computer chips can handle; therefore, scientists have long been searching for ways to reduce the heat without sacrificing diamond quality.

“If we want to implement diamond into silicon-based manufacturing, then we need to find a method of lower-temperature diamond growth,” said Yuri Barsukov, a computational research associate at PPPL who was the lead author of the study. “This could open a door for the silicon microelectronics industry.”

Finding the critical temperature

Past experiments into a process for making diamond, known as plasma-enhanced chemical vapor deposition, showed that acetylene can contribute to diamond growth. However, acetylene was also known to contribute to the growth of soot, which can grow on top of diamond and inhibits performance for optics, sensors and chips. The factors that determined whether the acetylene became diamond or soot were unclear.

“Now we have an answer,” Barsukov said. “Like water to ice, there is a critical temperature for the transition of one phase to another. Above this critical temperature, acetylene contributes mostly to diamond growth. Below this critical temperature, it contributes mostly to soot growth.”

According to the study, which was published in the journal Diamond & Related Materials, the critical temperature depends on several factors, including the concentration of acetylene and atomic hydrogen near the surface of the diamond.

“Hydrogen atoms don’t fuel diamond growth directly, but hydrogen dissociation, or breakdown, is crucial for transforming methane into acetylene and transporting atomic hydrogen to the diamond growth surface. These are both important for diamond growth,” said Princeton University Research Scholar Alexander Khrabry, an author of the paper. With more hydrogen near the surface, more diamond can form, even at lower temperatures.

Protecting quantum diamond

Perfecting the process for growing quality diamond at lower temperatures is just one piece of the puzzle to reliably making diamond for electronics. Some applications require a more complicated form of diamond in which some carbon atoms are removed, and a neighboring atom is replaced with nitrogen. This creates what scientists call nitrogen-vacancy centers or NV centers.

A separate study related to NV centers was published in the journal Advanced Materials Interfaces by researchers from PPPL, Princeton University and the Royal Melbourne Institute of Technology. This study looked at ways to protect the surface of this special material, which is known as quantum diamond, while keeping the NV centers intact.

“The electrons in this material don’t behave according to the laws of classical physics as heavier particles do. Instead, like all electrons, they behave according to the laws of quantum physics,” said Alastair Stacey, a managing principal research physicist and head of quantum materials and devices at PPPL who was a co-author on the study. One way researchers hope to harness these quantum behaviors is by making special bits called qubits. “The advantage of qubits is that they can hold much more information than regular bits can,” said Stacey. “This means that they can also give us much more information about their environment, making them extremely valuable as sensors, for example.”

Adding an even layer of hydrogen atoms

Attaching hydrogen to the diamond surface has implications both for microelectronics and quantum sensors. Hydrogen atoms can interact with diamond surfaces and lead them to conduct electricity, and, at the same time, they are needed as a starting point before attaching other, more complex molecules. The challenge is creating a single layer of hydrogen atoms evenly distributed on the surface of the quantum diamond without changing what lies beneath.

“People have been trying to control diamond surfaces for a very long time,” said Nathalie de Leon, an associate professor of electrical and computer engineering at Princeton University, associated faculty at PPPL and a co-author on the paper. “It’s an interesting fundamental science question because diamond is sort of a weird solid. You have a material that is exactly the same everywhere, and then at the very surface, it has to somehow bond to something else. But diamond is very inert, meaning it doesn’t want to react with things. It’s a very tight lattice, so it’s hard to get things in there. It’s also the hardest material in the world, so it’s very hard to polish and prepare in various ways.”

The study explores more reliable and less damaging techniques for adding that single layer of hydrogen atoms to the surface of the diamond so that it is ideal for certain quantum applications. It’s part of a broader area of research at the Lab on preparing diamond surfaces for quantum computing and sensing. PPPL opened its Quantum Diamond Laboratory in March 2024, making the Lab an ideal partner for such research.

The way atoms bond in diamond makes the material well suited for quantum applications, including quantum computing, secure communications and highly accurate measurements of temperature and magnetic fields.

“We need to precisely control the chemistry on the surface of the diamond using plasma, but plasma-surface interactions are not very well understood,” said Barsukov, who was also part of the second study. “People usually use a method of trial and error. So, we’re trying to shed light on some of the processes on the surface, just to make the picture a little bit clearer.”

Typically, this hydrogen layer is added by exposing the diamond to a hydrogen plasma under high heat. But, much like silicon in standard computer chips, the NV centers can’t handle this environment.

Creating a recipe book for quantum diamond

The research team sought to find better methods for making hydrogenated quantum diamond with the NV centers intact. “We’re writing a recipe book and characterizing different ways of properly hydrogenating diamond surfaces so that we understand how to do this better for a number of applications,” said Daniel McCloskey, the first author of the paper and a researcher at the School of Physics at the University of Melbourne.

The international research team investigated the traditional approach as well as the following two alternative hydrogenation methods:

- Forming gas annealing, which uses a mixture of hydrogen molecules and nitrogen gas (rather than a plasma made only of hydrogen).

- Cold plasma termination, which uses a hydrogen plasma but avoids direct heating of the diamond with the plasma.

Both alternative techniques produced hydrogenated diamond that could conduct electricity, but there are key differences and trade-offs. Specifically, the team found that the quality of the hydrogen layer made with forming gas annealing was highly dependent on the temperature used and the purity of the gas mixture. While no oxygen should be present during the experiment, some can leak in, and even that relatively small amount made a big difference.

“You have to get that oxygen off the diamond,” explained McCloskey, and that required temperatures upward of 900 degrees Celsius. McCloskey said developing ways to reduce and eliminate oxygen entering the reaction chamber is another important area of research that needs to be explored, adding that they had to go above and beyond the standard protocols to make it work.

The cold plasma termination method also created a hydrogen layer on the quantum diamond without damaging the NV centers. However, the trade-off is that the hydrogen layer made with cold plasma termination was of lower quality than the traditional heated approach.

Assessing the damage to NV centers

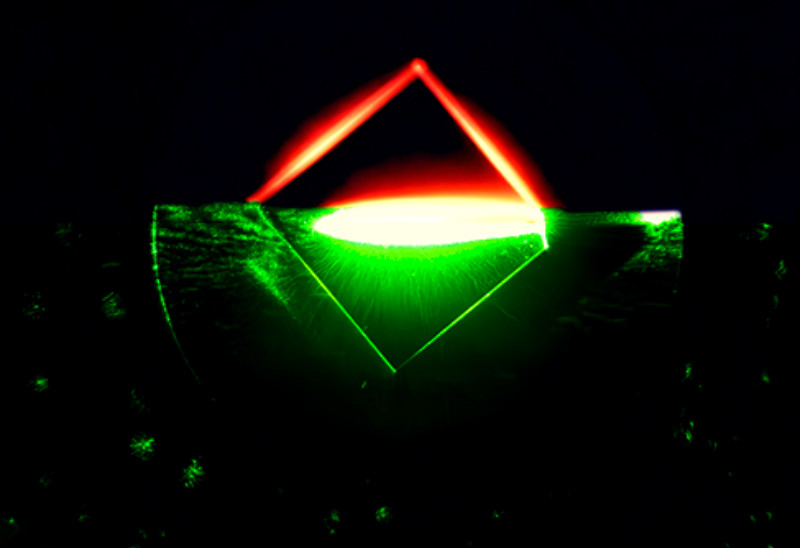

To investigate the impact of the hydrogenation methods on NV centers, the team used a technique called photoluminescence spectroscopy. “This is a way to peek in at a diamond sample that is full of NV centers by exciting them with green light and making them fluoresce,” Stacey explained. Neither of the two new hydrogenation methods affected fluorescence, even when the processes were repeated. However, the traditional heated plasma treatment resulted in an irreversible loss of nearly half of the NV center fluorescence.

Further research is required to perfect the new methods for reliably producing high-quality hydrogenated diamond surfaces with ideal NV centers. There are also many other avenues for PPPL and its collaborators to explore. While an even coating of hydrogen atoms might be the end goal for some applications, for others, it may just be the first step of many to create a custom surface involving other elements.