New Laser “Comb” Can Enable Rapid Identification of Chemicals With Extreme Precision

August 20, 2025 -- Optical frequency combs are specially designed lasers that act like rulers to accurately and rapidly measure specific frequencies of light. They can be used to detect and identify chemicals and pollutants with extremely high precision.

Frequency combs would be ideal for remote sensors or portable spectrometers because they can enable accurate, real-time monitoring of multiple chemicals without complex moving parts or external equipment.

But developing frequency combs with high enough bandwidth for these applications has been a challenge. Often, researchers must add bulky components that limit scalability and performance.

Now, a team of MIT researchers has demonstrated a compact, fully integrated device that uses a carefully crafted mirror to generate a stable frequency comb with very broad bandwidth. The mirror they developed, along with an on-chip measurement platform, offers the scalability and flexibility needed for mass-producible remote sensors and portable spectrometers. This development could enable more accurate environmental monitors that can identify multiple harmful chemicals from trace gases in the atmosphere.

“The broader the bandwidth a spectrometer has, the more powerful it is, but dispersion is in the way. Here we took the hardest problem that limits bandwidth and made it the centerpiece of our study, addressing every step to ensure robust frequency comb operation,” says Qing Hu, Distinguished Professor in Electrical Engineering and Computer Science at MIT, principal investigator in the Research Laboratory of Electronics, and senior author on an open-access paper describing the work.

He is joined on the paper by lead author Tianyi Zeng PhD ’23; as well as Yamac Dikmelik of General Dynamics Mission Systems; Feng Xie and Kevin Lascola of Thorlabs Quantum Electronics; and David Burghoff SM ’09, PhD ’14, an assistant professor at the University of Texas at Austin. The research appears today in Light: Science and Applications.

Broadband combs

An optical frequency comb produces a spectrum of equally spaced laser lines, which resemble the teeth of a comb.

Scientists can generate frequency combs using several types of lasers for different wavelengths. By using a laser that produces long wave infrared radiation, such as a quantum cascade laser, they can use frequency combs for high-resolution sensing and spectroscopy.

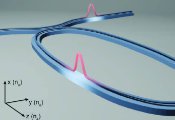

In dual-comb spectroscopy (DCS), the beam of one frequency comb travels straight through the system and strikes a detector at the other end. The beam of the second frequency comb passes through a chemical sample before striking the same detector. Using the results from both combs, scientists can faithfully replicate the chemical features of the sample at much lower frequencies, where signals can be easily analyzed.

The frequency combs must have high bandwidth, or they will only be able to detect a small frequency range of chemical compounds, which could lead to false alarms or inaccurate results.

Dispersion is the most important factor that limits a frequency comb’s bandwidth. If there is dispersion, the laser lines are not evenly spaced, which is incompatible with the formation of frequency combs.

“With long wave infrared radiation, the dispersion will be very high. There is no way to get around it, so we have to find a way to compensate for it or counteract it by engineering our system,” Hu says.

Many existing approaches aren’t flexible enough to be used in different scenarios or don’t enable high enough bandwidth.

Hu’s group previously solved this problem in a different type of frequency comb, one that used terahertz waves, by developing a double-chirped mirror (DCM).

A DCM is a special type of optical mirror that has multiple layers with thicknesses that change gradually from one end to the other. They found that this DCM, which has a corrugated structure, could effectively compensate for dispersion when used with a terahertz laser.

“We tried to borrow this trick and apply it to an infrared comb, but we ran into lots of challenges,” Hu says.

Because infrared waves are 10 times shorter than terahertz waves, fabricating the new mirror required an extreme level of precision. At the same time, they needed to coat the entire DCM in a thick layer of gold to remove the heat under laser operation. Plus, their dispersion measurement system, designed for terahertz waves, wouldn’t work with infrared waves, which have frequencies that are about 10 times higher than terahertz.

“After more than two years of trying to implement this scheme, we reached a dead end,” Hu says.

A new solution

Ready to throw in the towel, the team realized something they had missed. They had designed the mirror with corrugation to compensate for the lossy terahertz laser, but infrared radiation sources aren’t as lossy.

This meant they could use a standard DCM design to compensate for dispersion, which is compatible with infrared radiation. However, they still needed to create curved mirror layers to capture the beam of the laser, which made fabrication much more difficult than usual.

“The adjacent layers of mirror differ only by tens of nanometers. That level of precision precludes standard photolithography techniques. On top of that, we still had to etch very deeply into the notoriously stubborn material stacks. Achieving those critical dimensions and etch depths was key to unlocking broadband comb performance,” Zeng says. In addition to precisely fabricating the DCM, they integrated the mirror directly onto the laser, making the device extremely compact. The team also developed a high-resolution, on-chip dispersion measurement platform that doesn’t require bulky external equipment.

“Our approach is flexible. As long as we can use our platform to measure the dispersion, we can design and fabricate a DCM that compensates for it,” Hu adds.

Taken together, the DCM and on-chip measurement platform enabled the team to generate stable infrared laser frequency combs that had far greater bandwidth than can usually be achieved without a DCM.

In the future, the researchers want to extend their approach to other laser platforms that could generate combs with even greater bandwidth and higher power for more demanding applications.

“These researchers developed an ingenious nanophotonic dispersion compensation scheme based on an integrated air–dielectric double-chirped mirror. This approach provides unprecedented control over dispersion, enabling broadband comb formation at room temperature in the long-wave infrared. Their work opens the door to practical, chip-scale frequency combs for applications ranging from chemical sensing to free-space communications,” says Jacob B. Khurgin, a professor at the Johns Hopkins University Whiting School of Engineering, who was not involved with this paper.

This work is funded, in part, by the U.S. Defense Advanced Research Projects Agency (DARPA) and the Gordon and Betty Moore Foundation.