Infrared Innovation Heats Up with a Nano-Tunable Filter

October 2, 2025 -- A new nanoengineered approach promises to make infrared spectrometers dramatically cheaper, more compact, and more robust — by replacing bulky moving optics with a heat-tunable metasurface. This breakthrough from TMOS researchers could bring high-end infrared sensing out of the lab and into handheld, field-deployable devices.

Taming the Infrared with Heat

Conventional infrared spectrometers rely on gratings, prisms, or mechanical scanning systems to split light into its component wavelengths. While effective, these components are typically large, expensive, and prone to mechanical wear.

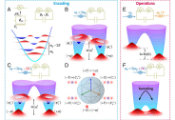

The TMOS team has instead developed a thermo-optically tunable bandpass filter. Etched into a thin layer of silicon on a sapphire base, this metasurface shifts its transmission window when heated or cooled. By simply changing the temperature, researchers can select which slice of the infrared spectrum passes through — no moving parts required.

This silicon-based approach makes the filter not only scalable for manufacturing, but also highly robust, offering a pathway to miniaturised, field-ready devices.

From Design to Prototype

The researchers fabricated several metasurface designs, including both parallel and crossed patterns to reduce sensitivity to light polarisation. These patterns were etched into a ~1.5 µm silicon film supported on a 470 µm sapphire substrate.

Testing revealed that across normal operating temperatures (25 °C to 420 °C), the filter’s central passband shifted by about 80 nm. At cryogenic temperatures, shifts of up to 140 nm were observed.

To demonstrate practical use, the filter was applied to identify common materials such as polymer tape, zinc selenide, and clear plastics including PET and LDPE — each distinguishable by their unique infrared “fingerprints.”

Why This Matters

Infrared spectroscopy is invaluable for chemical analysis, environmental monitoring, industrial processing, and recycling, but today’s systems remain bulky and costly — often tens of thousands of dollars.

By contrast, TMOS’s metasurface filters could be produced at scale for less than AU$1 each. This opens the door to lightweight, affordable devices that can perform rapid on-site testing — from food quality checks to soil contamination analysis and waste-sorting facilities.

Challenges and Next Steps

While promising, challenges remain. The achievable tuning range (~80 nm under typical conditions) may limit spectral coverage. Long-term stability through repeated heating and cooling, as well as integration into full spectrometer systems, must also be addressed.

Future directions include extending the tuning range, optimising power requirements, and combining multiple filters to achieve broader coverage.

This research is published in Laser & Photonics Reviews in the article: “Thermo-Optically Tunable Mid-Infrared Bandpass Filters Comprising Ultra-Thin Silicon-on-Sapphire Metasurfaces” by Benjamin J. Russell et al.

Conducted within the ARC Centre of Excellence for Transformative Meta-Optical Systems (TMOS), this work highlights how meta-optics is transforming spectroscopy into a more accessible and practical technology for the real world.