Bluefors Lab Expansion Helps QuantrolOx Go Beyond Quantum EDGE

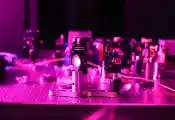

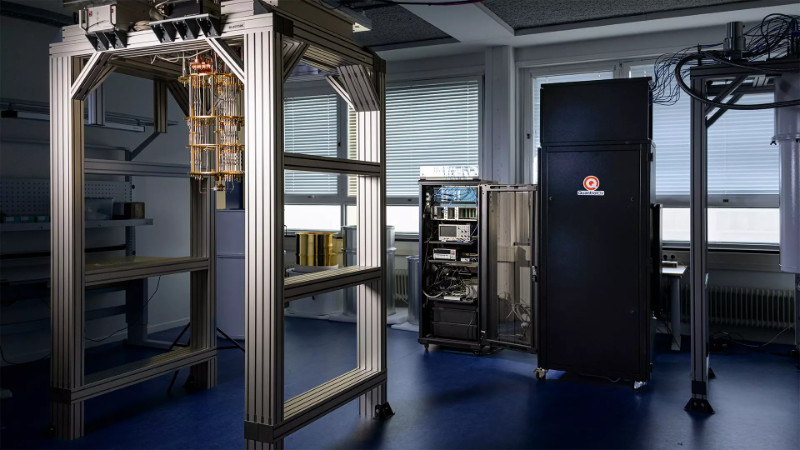

June 3, 2024 -- Following the recent expansion of the Bluefors Lab in Delft, we are happy to share the news that QuantrolOx – leaders in automating the bring-up, characterization, and tuning of quantum computers – will be the first team to utilize the newly-installed XLD1000sl Dilution Refrigerator.

QuantrolOx has been a long-term customer of Bluefors Lab, using the facility’s LD system to test the development of Quantum EDGE, its first product designed to reduce the time needed for fundamental experiments by automating many of the vital processes for quantum computers (such as bring-up, characterization and tuning).

Vishal Chatrath, QuantrolOX’s Co-Founder, points out that quantum computers are very sensitive to the quality of the cryogenic environment in order to maintain peak performance. “The Bluefors Lab has consistently provided us with a high-quality environment which allows us to speed up the development of Quantum EDGE and ensure the software works out of the box. Today Quantum EDGE is the only software of its type to be developed and tested 24/7 on an actual quantum computer.”

The Bluefors Lab enables startups, research groups, and other organizations to easily carry out quantum technology research and development. For QuantrolOx, the lab has helped take them from early product development to the launch of Quantum EDGE. By utilizing the LD400 in the lab, they were also able to test the integration of their software with the suite of measurement electronics that are included in the system, as well as the additional instruments that they brought to the environment themselves.

“Being able to test on a dedicated system and integrate leading control electronics from providers such as Qblox, Quantum Machines and Zurich Instruments, has been hugely beneficial. It has helped us deliver incredible value to our customers, giving them unprecedented performance to help them accelerate their quantum chip development. Quantum EDGE smashes previous industry benchmarks for single qubit bring-up, characterization and testing from 1-2 days to under 10 minutes, providing the Quantum Industry a viable path to developing automated industrial processes that will enable better and lower cost quantum chips,” Vishal reveals.

Moving up to the new XLD1000sl system will help QuantrolOX take their software even further. The base configuration of the XLD includes a Microwave Readout Module with TWPA, and is designed for more demanding experiments that require a larger experimental space and superior performance.

Vishal says, “With the new system QuantrolOx now has the ability to test its software with multiple electronics and multiple types of QPUs at the same time. It also gives us the ability to work with larger QPUs, allowing us to test new techniques and further improve the performance of our software.”

For companies like QuantrolOx, access to a dedicated testing environment in which an actual quantum computer can be operated is a fundamental requirement for successful development. However, not many small start-ups have the capability or resources to set up and operate their own dilution refrigerator. This is where the Bluefors Lab service offers many advantages.

“The creation of a service-based lab by Bluefors turned out to be perfect timing for us, and having the Lab personnel available on site to help QuantrolOX make adjustments to the control electronics remotely saves us a lot of time travelling to and from the Lab,” Vishal adds.

QuantrolOx’s successful and rapid development of Quantum EDGE at Delft is testament to the power and usefulness of Bluefors Lab for startups and organizations working at the cutting edge of quantum technology. By providing the tools, measurement infrastructure, and expertise to carry out R&D on benchmark systems without needing to invest in purchasing them, the Lab enables teams to focus on results.