OQC and Fraunhofer EMFT Partner to Strengthen Quantum Fabrication Capabilities

Oxford, October 05, 2025 -- Oxford Quantum Circuits (OQC) and the Fraunhofer Institute for Electronic Microsystems and Solid State Technologies EMFT today announced a strategic partnership designed to accelerate the industrialisation of superconducting quantum technologies. By merging OQC’s system-level quantum expertise with Fraunhofer’s advanced fabrication capabilities, the partnership charts a new course towards scalable, manufacturable quantum computing.

The collaboration represents a pivotal step in OQC’s journey towards fabless production, aligning superconducting quantum devices with industry-standard, CMOS-compatible processes that underpin global semiconductor manufacturing.

Quantum Computing’s Defining Moment: From Laboratory to Factory Floor

The quantum industry is entering an era where success is measured not by qubit count alone but by the ability to scale – to build quantum processors repeatably, reliably, and at industrial quality.

John M. Martinis, Nobel Prize in Physics 2025, has underscored the importance of leveraging semiconductor technologies for superconducting systems.

OQC and Fraunhofer are responding decisively. Their partnership demonstrates how the superconducting community is now meeting the challenge head-on, adopting industrial-grade tooling and fabrication standards to make scalability a reality.

By aligning with CMOS-compatible processes, both organisations are reinforcing confidence among investors, customers, and policymakers that quantum hardware can mature within the frameworks that built modern computing.

Dr. Thomas Mayer, Project Lead Fraunhofer EMFT, commented:

“Transferring the OQC superconducting qubit technology to the Fraunhofer EMFT CMOS-line is a highly fascinating technological task and a prime example for bridging semiconductor research and industrial production.”

Scalability: OQC’s Vision for the Quantum Economy

For OQC, this partnership is a deliberate move towards a fabless quantum model – where world-class design and system engineering are decoupled from physical fabrication, unlocking the same kind of global scaling that transformed the semiconductor industry.

“The future of scale is a fabless world,” said Connor Shelly, VP of Materials Science and Device Engineering at OQC. “Partnering with Fraunhofer allows us to realise that vision – combining cutting-edge industrial processes with the deep fabrication expertise that has powered quantum innovation to date.”

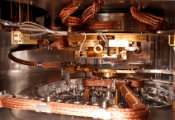

OQC’s research and innovation continue to push boundaries in superconducting qubit development. The company’s recent publication in Advanced Materials explores the use of high-purity sapphire substrates to improve overall qubit quality and coherence. The study incorporated advanced machining capability to allow wafer-scale production of sapphire-based superconducting Quantum Processing Units (QPUs). This work combined fundamental research with a focus on improving quality and yield of our devices.

Similarly, OQC has been investigating the key element of superconducting qubits: the Josephson junction. Assessing the barrier variation through a means of advanced microscopy and electrical measurements, as well as describing junction tuning with a theoretical framework. This gives OQC the tools to understand the relationship between process variables and junction reproducibility at manufacturing scale.

OQC’s work goes beyond material science: it signals a broader engineering philosophy that drives its hardware roadmap – scientific precision meets industrial pragmatism. By advancing both materials engineering and qubit architecture, OQC is building the foundation for quantum systems that perform at scale and can be manufactured through industrial partnerships, like the one with Fraunhofer.

Where Quantum Meets Industry: Fraunhofer’s Role in Bridging Research and Manufacturing

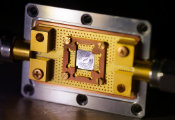

Fraunhofer EMFT brings a unique capability to the partnership: translating quantum research into scalable, CMOS-compatible manufacturing processes. Its Quantum CPU Pilot Line demonstrates how established semiconductor infrastructure can now directly support superconducting qubit fabrication – a bridge that brings quantum technology firmly into the domain of industrial manufacturing.

“We are thrilled to deploy the Fraunhofer EMFT quantum pilot line as standard manufacturer of OQC quantum processing units.” said Prof. Christoph Kutter, Director of Fraunhofer EMFT. “Putting our world-class semiconductor processing capabilities into use for manufacturing scalable quantum hardware is a true win-win situation for both partners and for the whole quantum computing industry.”

The Fraunhofer-Gesellschaft, headquartered in Germany, is one of the world’s leading organisations for applied research. It plays a major role in innovation by prioritising research on cutting-edge technologies and the transfer of results to industry to strengthen Germany’s industrial base and for the benefit of society as a whole. Since its founding as a nonprofit organization in 1949, Fraunhofer has held a unique position in the German research and innovation ecosystem.

Recent Fraunhofer EMFT publications underline this maturity. Collectively, these publications demonstrate that Fraunhofer’s fabrication environment is not only capable of producing high-performance superconducting qubits, but doing so using industrial-grade methods. The consistency of these results across multiple process nodes confirms that the superconducting platform is now ready for scale-up through standard CMOS-compatible lines – the same infrastructure that powers today’s global semiconductor supply chain.

Collaboration as the Catalyst for Scale

This partnership reflects a collective movement within the superconducting ecosystem – from initiatives like Supreme to the growing emphasis on shared standards and cross-institutional collaboration.

Both OQC and Fraunhofer see scaling not as a competitive race but as a shared challenge. The transition from research-scale to industry-scale quantum computing demands open collaboration, reproducibility, and alignment around manufacturable technologies.

“Scaling quantum computing isn’t just an engineering problem – it’s an ecosystem challenge,” added Shelly. “We need to align processes, materials, and standards if we’re going to reach the impact we all envision.”

Towards an Industrial Quantum Future

The OQC–Fraunhofer collaboration lays the foundation for next-generation superconducting qubits that can be manufactured at volume – an essential step towards real-world quantum deployment.

With further joint publications, deeper technology exchanges, and new industrial partners on the horizon, this partnership signals a turning point in the evolution of quantum computing: one where superconducting technology moves beyond the lab, into scalable, commercial reality.